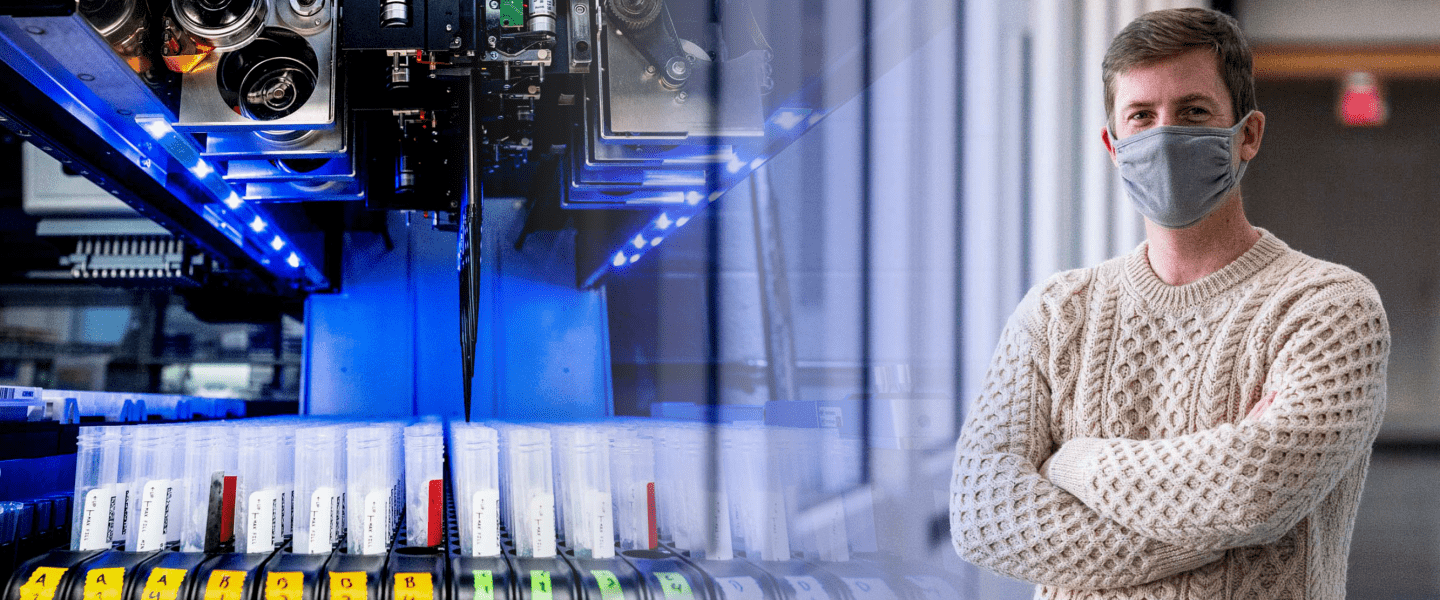

The automated liquid-handling robot is large enough to claim a 12-foot-by-4-foot expanse of lab table space in its unexpected home in UVA Health’s West Complex. Last summer, University of Virginia assistant biology professor John Campbell and his neuroscience team were customizing the Hamilton Company machine and its pipetting arms for ongoing, funded research projects in their own lab space.

Their projects explore the circuitry of the vagus nerve – a cranial nerve that carries a wide range of signals from the human digestive system and organs to the brain, and vice versa.

Asst. Biology Prof. John Campbell offered his lab’s robot to UVA for its COVID testing efforts.

The robot was playing a central role in the lab’s discoveries about how the vagus nerve controls the digestive, cardiovascular and immune systems.

When UVA decided to welcome students back on Grounds for classes last fall, though, the University needed to dramatically improve its ability to test students, faculty and staff in order to quickly identify COVID cases and limit potential outbreaks. So, when the Department of Biology’s chair, Deborah Roach, emailed faculty to ask whose research lab might have a large-scale liquid handler that the University could use to scale up COVID testing efforts, Campbell offered his robot.

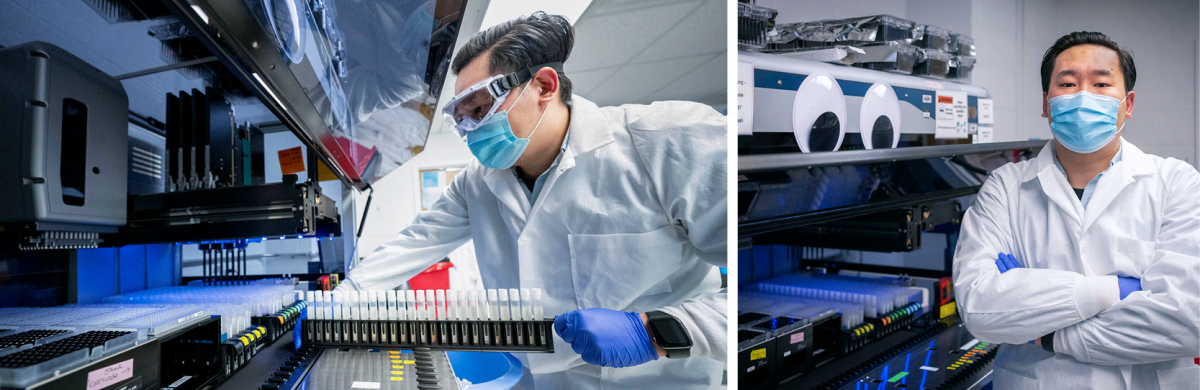

With a pair of oversized googly eyes affixed to its front panel, the repurposed robot is playfully referred to as “Rosie,” a nod to a line from Paul Simon’s song, “Me and Julio Down by the Schoolyard.” (“Goodbye to Rosie, the queen of Corona …”) Rosie now operates six days a week, with two shifts of lab workers processing as many as 3,500 saliva samples a day, in what used to be an empty space on the fifth floor of the Old Medical School Building. That’s more than twice as many vials processed daily by lab workers in the fall semester before Rosie was reprogrammed and came online in February.

An automated liquid-handling robot, the Hamilton NGS Star machine has allowed UVA to ramp up its COVID testing capabilities. With the robot, the Be SAFE lab processes as many as 3,500 saliva samples a day.

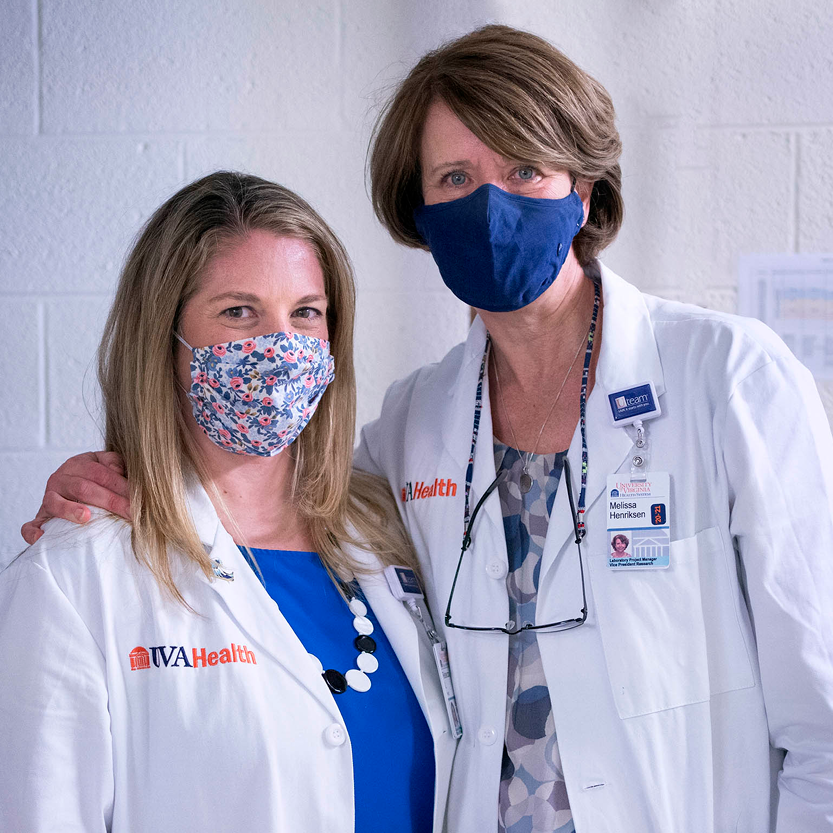

Under the guidance of Melissa Henriksen, project manager for the Be SAFE Lab that Rosie serves, the lab played a critical role in identifying a dramatic spike in positive COVID cases soon after Rosie was activated. The lab’s ability to quickly process test samples collected from four sites on Grounds and to relay those test results to University leadership led to a series of temporary restrictions on University activities, on and off Grounds, announced on Feb. 19. By the end of February, after the lab reported a measurable decline in the number of positive COVID cases and in the positivity rate among students, faculty and staff, UVA lifted most of those restrictions.

"With a pair of oversized googly eyes affixed to its front panel, the lab’s robot is playfully referred to now as ‘Rosie,’ a nod to a line from Paul Simon’s song, ‘Me and Julio Down by the Schoolyard.’ (‘Goodbye to Rosie, the queen of Corona …’)"

“Many faculty, staff and researchers came together to help our saliva screening effort at UVA this year,” said Melur “Ram” Ramasubramanian, the University’s vice president for research. “Acquiring John Campbell’s robot allowed us to get our lab up and running more quickly, and to get to our goal of processing 3,500 samples a day. Our lab now offers COVID-19 testing to all students once a week, helping to stop the spread of the virus in our community.”

Starting From Scratch

UVA’s effort to build its own COVID-testing lab for the University community began last August. Modeling its effort after the testing program at the University of Illinois, UVA selected a saliva-based, polymerase chain reaction test, commonly called the PCR. It was considered a reliable option that was less expensive and less invasive than nasal swabs.

The director for university engagement at UVA’s Applied Research Institute, Henriksen has a Ph.D. in biological chemistry and has run two of her own research labs at UVA, as well as one previously at Fordham University. Looking back at the whirlwind six weeks that transformed the selected space – most of which was formerly an OB/GYN billing office – into a working lab, Henriksen said that it seemed like “the most intense thing I’ve ever been involved with.”

"Acquiring John Campbell’s robot allowed us to get our lab up and running more quickly, and to get to our goal of processing 3,500 samples a day. Our lab now offers COVID-19 testing to all students once a week, helping to stop the spread of the virus in our community". – Melur “Ram” Ramasubramanian, the University’s vice president for research

Building the Be SAFE lab from scratch involved knocking down a wall in the old billing offices to create a larger space for lab workers and the necessary equipment: tens of thousands of chemical agents, test tubes and pipette tips. The refrigerator used to store reagents had to be certified as medical-grade, and lab certifications required the installation of a generator in case of a power outage. By the end of October, after months of seven-day work weeks for Henriksen and her team, the lab’s equipment had been set up and installed in time to begin processing saliva samples. UVA arranged for students, staff and faculty teaching on Grounds to submit samples in the Central Grounds parking garage, where they were asked to drool into vials that were then sealed in bags and delivered across Grounds to the lab.

“When we started on Sept. 5, there was nothing in there,” Henriksen said of the Be SAFE lab. “Transforming this from a billing office into a COVID testing lab in a matter of weeks, it’s crazy to think about it. But it’s the most rewarding and important thing I’ve been involved with in my career.”

Moving Rosie

Campbell and Henriksen can joke about it now, but moving Campbell’s robot to the Be SAFE lab nearly required some “Ocean’s Eleven”-level heist maneuvers. Transporting the $231,000 machine across Grounds required a special crate from its manufacturer in Reno, Nevada, to get it safely out of Campbell’s lab in Gilmer Hall. With Gilmer undergoing renovation, there was a tight window to get the robot out before that wing of the building was sealed off for construction work. Because of supply chain delays, Henriksen and Campbell learned the crate was scheduled to arrive one day too late.

In the days before Gilmer was sealed shut, Henriksen arranged for movers specializing in scientific equipment to load the robot onto Gilmer’s freight elevator and move it to the loading dock behind the Chemistry Building.

“I’m a project manager, and I do a lot of thinking about risk assessment,” Henriksen said. “But entombment was not a risk that I had considered as a possibility. That was funny. And stressful.”

But then she was forced into quarantine when her husband, Siva Vaidhyanathan, a professor in UVA’s Department of Media Studies, tested positive for COVID-19. Becca Latimer, the director of proposal development in the Office of the Vice President for Research and Henriksen’s indispensable partner in the set-up and running of the Be SAFE Lab, stepped in to manage the move.

Be SAFE Lab’s project manager Melissa Henriksen, right, and Becca Latimer, director of proposal development in the Office of the Vice President for Research, left.

Then, on the last possible day to remove the robot from the building, the movers didn’t show. David Glover, a project associate with the Department of Biology, called in some help from the University’s McCormick Zone Facilities Management team under the supervision of Jim Comer. The makeshift movers saved the day, carrying the robot out of the building just before it was sealed off for renovation. The crate arrived a day later, and a team of Hamilton Company technicians locked it safely in storage until it could be moved to its new home a few weeks later.

“It’s not the easiest thing to move around. It weighs about 600 pounds, and it’s a very delicate tool,” said Campbell, who came to Gilmer to watch the robot get moved. “We had one shot, basically, to get it out of my lab, down through the freight elevator and out of the building, or it would have been sealed in Gilmer for two years. But I have to say, Mel [Henriksen] was the right person for that job. She was just unflappable. Every time there was some new, seemingly insurmountable obstacle to the success of this plan, Mel found a way over it.”

Rosie Finds Her Higher Calling

Before it could help ramp up the COVID testing on Grounds that began last fall, Campbell’s robot needed to be re-programmed to handle its new task of loading and processing a plate carrying 376 test tube samples. That required consulting visits by Hamilton technicians and months of software coding work before its Be SAFE debut at the start of February.

Optimizing the new coding to better suit the Be SAFE lab’s protocol fell on Pu (Bruce) Zhang, a mechanical engineering graduate student and staff technologist for the lab. Zhang’s engineering background and experience working with the UVA School of Medicine’s Department of Surgery and other biological research projects came in handy.

“I probably spent four to five weeks getting used to everything and learning the interface and coding,” Zhang said. “After that, it took me about two weeks to learn how to operate the robot. The first time we ran a plate of saliva samples with the robot, it took almost an hour to do one plate. Now, with the ‘fork-join model’ program that was created to simultaneously pipette all the samples and scan each sample’s barcode, we’re saving roughly 15 to 20 minutes per plate.”

Pu (Bruce) Zhang, a UVA mechanical engineering graduate student and staff technologist for the Be SAFE lab, loads a rack of saliva specimens on the robot’s deck for testing.

With Rosie’s processing speed increasing the lab’s capabilities, UVA was able to require students to get tested weekly. Faculty and staff are also able to visit one of four testing sites on Grounds to submit a sample. Once samples arrive in the lab, they are scanned into an internal, secure log for processing. Test results are generated typically within two days, and each one is assigned a barcode that is then reported securely to a high-security server used for highly sensitive data. Results are transferred regularly to UVA Medical Records and then released into “MyChart,” where patients can see their own results.

Since the Be SAFE Lab reported the University’s highest total of new COVID cases (229) on Feb. 16, the first day of temporary restrictions imposed on Grounds, the number of new cases has been dropping, with the University’s seven-day positivity rate remaining well below 1% through April. The increased monitoring and subsequent case reduction have enabled the University to return most restrictions to match the state’s guidelines and plan an in-person graduation celebration for the classes of 2020 and 2021.

“When we started on Sept. 5, there was nothing in there. Transforming this from a billing office into a COVID testing lab in a matter of weeks, it’s crazy to think about it. But it’s the most rewarding and important thing I’ve been involved with in my career." – Melissa Henriksen, the Be SAFE Lab’s project manager

Meanwhile, Campbell’s robot and Henriksen’s lab team continue to process test samples six days a week, 13 hours a day. Campbell’s own research lab has been able to resume its research after UVA purchased replacement machinery to make up for Rosie’s departure.

“There was a lot of pride tinged with a little sadness to give up the robot, but we knew it was going to be doing something very important for the UVA community,” Campbell said. “It’s helping us stay ahead of the next outbreak and any potential surges, and that’s definitely a higher calling for that machine.”

Images courtesy of Sanjay Suchak.